PIW Definitions / Ratings

In the world of conveyor belts, the ability to withstand tension is a crucial aspect of their design. This strength is quantified in the United States using a measurement known as Pounds per Inch of Width, or PIW. In other regions, the rating might be expressed in metric units like newtons per millimeter (N/mm) or kilonewtons per meter (kN/m), specifying the ultimate breaking-strength of the belt. It's important to note that a belt's top and bottom covers contribute minimally to its overall strength or tension rating.

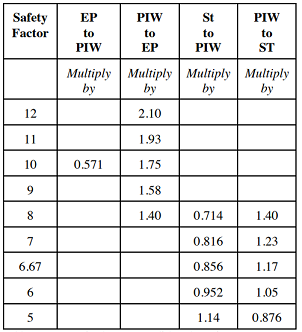

PIW RATINGS EXPLAINED

In the world of conveyor belts, the ability to withstand tension is a crucial aspect of their design. This strength is quantified in the United States using a measurement known as Pounds per Inch of Width, or PIW. In other regions, the rating might be expressed in metric units like newtons per millimeter (N/mm) or kilonewtons per meter (kN/m), specifying the ultimate breaking-strength of the belt. It's important to note that a belt's top and bottom covers contribute minimally to its overall strength or tension rating.

Every conveyor structure necessitates a belt with a specific tension rating. This rating reflects the amount of force the belting can endure. Overloading the belt with excessive material, takeup weight, or steep inclines can lead to various issues, including belt breakage. Higher-rated tension belts demand an even closer match with the structure and the components involved in the conveyor system.

The choice of a specific belt tension rating for a conveyor structure is influenced by several factors:

- Structure Length: The overall length of the conveyor structure affects the belt's tension requirements.

- Incline Angle: The angle at which the conveyor operates plays a significant role in determining the appropriate tension rating.

- Desired Capacity: The conveyor's intended capacity is a critical factor in selecting the right belt tension.

- Belt Width: The width of the belt is another important consideration for ensuring proper tension.

- Drag and Inertia: The effects of rolling components, such as idlers and pulleys, impact the belt's tension requirements.